EBAK FILLING MACHINE

The Filling Machine with Pistol is the perfect solution for both large food industries and confectionery workshops.

Suitable for a wide range of filling types like pralines, jams, confectionery creams, honey, yogurt, creamy vegetable or animal origin kinds of butter, creamy masses of cheese-made products, whipped cream, even for masses with sliced food materials (herbs, nuts, olives…), etc.

KEY FEATURES

Filling Machine with Pistol

- Hopper’s capacity: 40lt

- Motor’s power from 0,25 to 0,55KW

- Food Grade (FDA) silicone tube. Standard length 2m, 4m available on request

- Minimum dosing quantity 5ml. Maximum dosing quantity whole hopper

- Standard Model controlled by Potentiometer and timer. Model equipped with PLC and touch screen (HMI) available on request

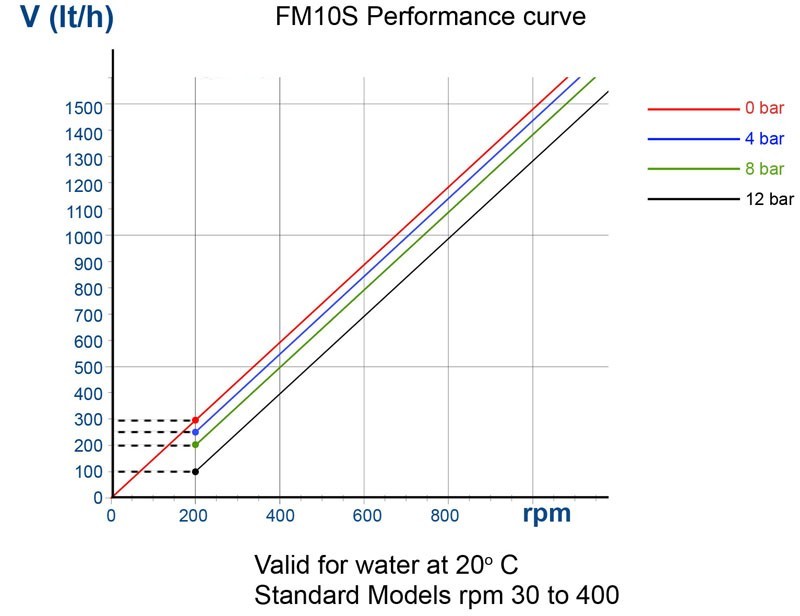

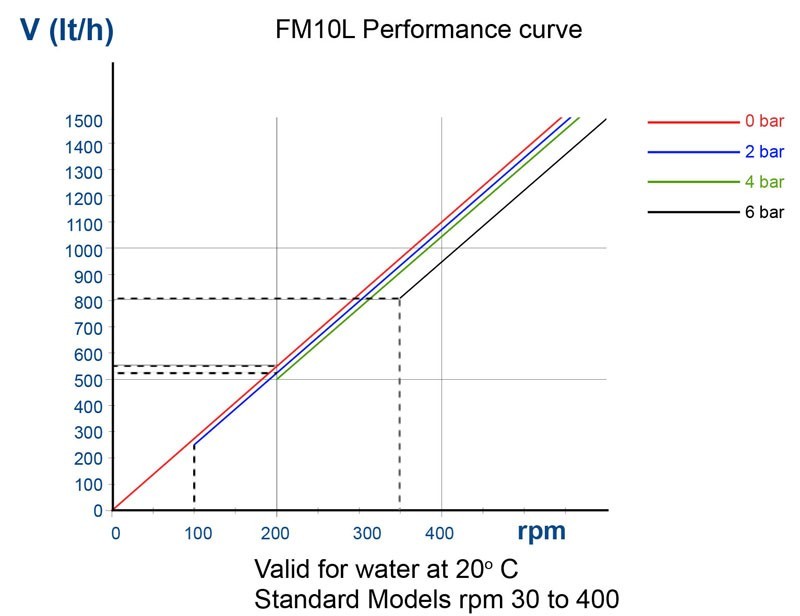

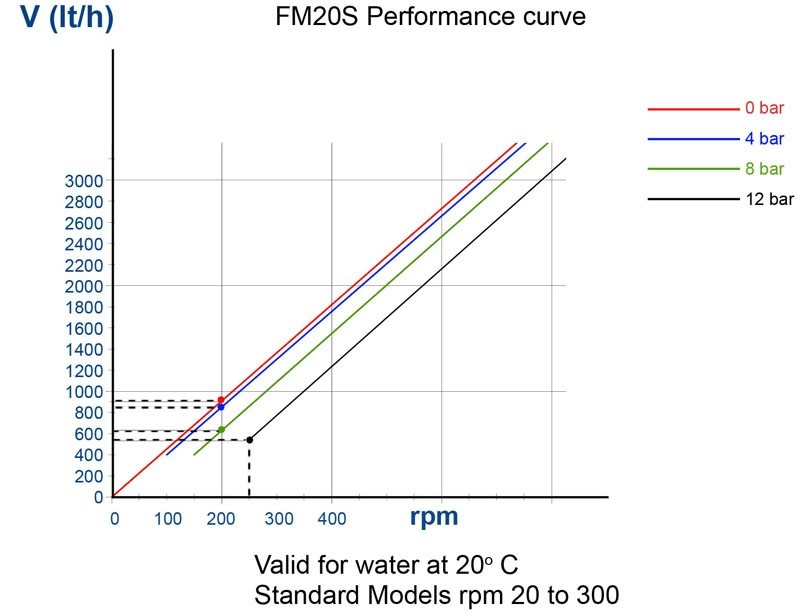

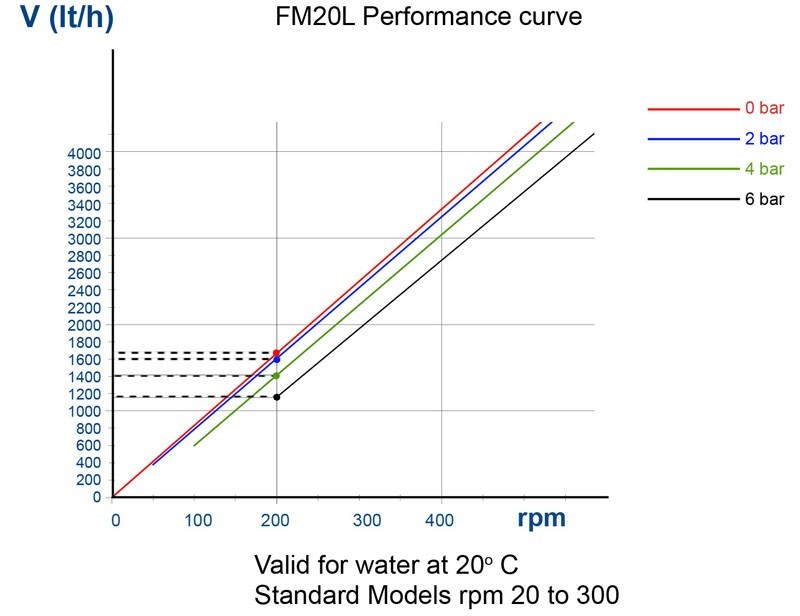

EBAK’s FM standard models

performance diagrams

When FM is integrating into complex conveying and distributing systems,

it generates automated filling lines.

Let’s see some examples.

Wafer praline depositing line

- Hopper’s capacity: 40lt

- Motor’s power from 0,25 to 0,55KW

- Food Grade (FDA) Construction

- Deposits a thin layer of praline (chocolate/cream/jam etc.) onto wafer plates. It can create a block of wafers (up to 9), or continuously feed a praline waterfall with wafer plates. Precise dosing, high productivity, reliability.

FILLING MACHINE WITH CONVEYOR

- Hopper’s capacity: 40lt

- Motor’s power from 0,25 to 0,55KW

- Food Grade (FDA) Construction

- At FMwCNV the head does a perpendicular movement directed by a pneumatic piston. Initially, the head moves down and when it reaches the lower point triggers the filling. On filling completion, the head moves up. The lower position can be regulated by a delimiter knob.

AUTOMATIC BENCH XY for FILLING/ TOPPING/ DEPOSITING

- Hopper’s capacity: 40lt

- Motor’s power from 0,25 to 0,55KW

- Food Grade (FDA) Construction

- XY bench is equipped with PLC and touch screen (HMI) and has changeable heads. The adjustable running parameters let you automate the filling process of products already placed into trays with cases.

tailor-made solutions cases

LAYER CAKE DEPOSITION I

LAYER CAKE DEPOSITION II

.

Relevant Posts

AUTOMATIC WAFER TOPPING MACHINE

AUTOMATIC WAFER TOPPING MACHINE by EBAK . EBAK's Clients

Wafer topping line. Installation at Central Macedonia

Play Video PLAY on VIMEO Wafer praline depositing line Deposits a thin layer of praline [...]

Indonesian company Prima Top Boga chose EBAK’s filling line ECL208C

Play Video PLAY on VIMEO The Indonesian company "Prima Top Boga" choose ECL208C filling line [...]

Quiches Tarts line Installation at Melbourne

Play Video PLAY on VIMEO Australian company "Melbourne chef" choose TML and FM machines to automate [...]