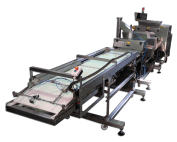

ALD – DOUGH PRODUCTS PRODUCTION LINE

BREADSTICKS, COOKIES, VARIOUS SNACKS & BISCUITS

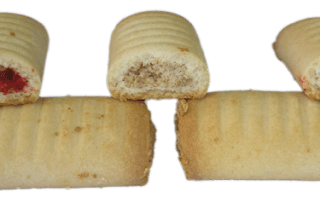

WITH or WITHOUT SEED COATING, WITH or WITHOUT FILLING

production of bread-sticks, grisini, cookies, stuffed or twisted products, bagels, bread rings, etc.

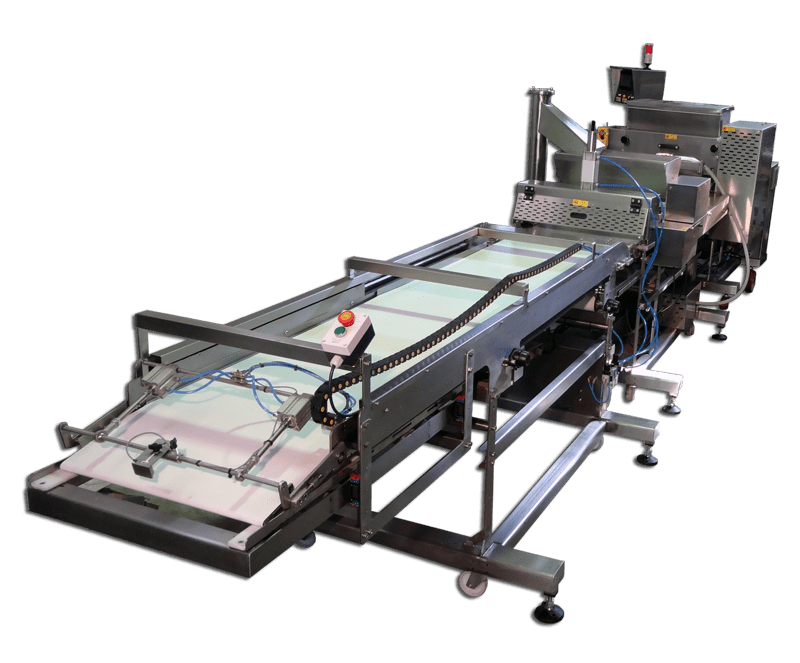

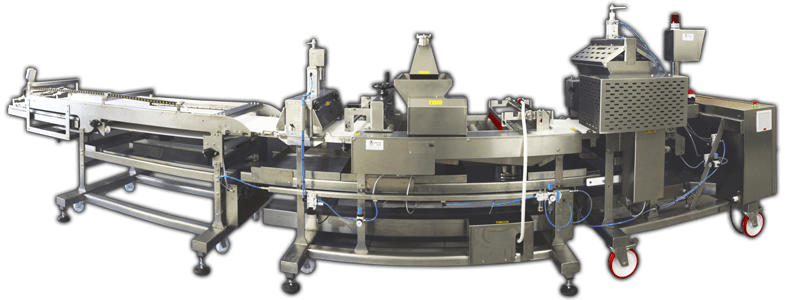

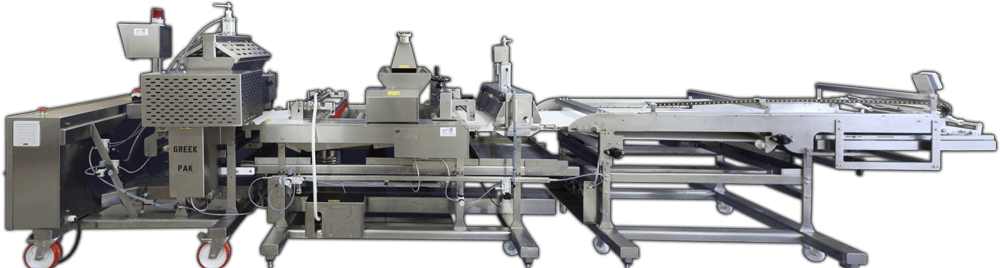

ALD is a very flexible and productive line that handles the dough gently.

It is suitable to operate with many kinds of bakery and pastry dough (with moisture less than 70%) like wheat, whole wheat, rye, multigrain, stiff, soft, with yeast or not, cookies dough, gluten-free, even dough with nut pieces (or other sliced food material).

The line consists of an extruder, a seeding unit, and optionally a placing at pans unit.

The extruder uses two specially designed (patented) rollers to extract the dough.

The easily changeable molds determine the contour of the products.

In combination with various add on systems, produces many kinds of products.

Using a guillotine, we can cut strips of dough to the desired length. (Bread-sticks, grisini, rusks, baton sale, croutons, etc.)

With the horizontal knife, we can produce cookies in any shape we like, according to the chosen mold.

The braiding unit produces braided cookies (like the famous Greek “koulourakia”).

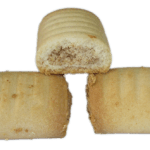

By adding a filling unit, we can produce stuffed products.

The unique patented ring system gives us the potential to produce rings of dough in many diameters (koulouri, simit, govrige, etc.)

The seeding unit (SD) allows us to sprinkle seeds (or sugar, salt, powder, nuts, syrup, egg, etc.) onto dough products.

The key features of the seeding unit are:

– Uniformly coating on top and bottom of the product.

– Recycling system for the liquids & seeds.

– Multi seeding systems are available.

– Choices between wired belt or fabric conveyors.

A tunnel oven of the same width can be directly attached to an ALD line. Alternatively, we can use the placing at trays unit (DP), to get our products onto baking trays or to feed a tunnel oven with greater conveyor width than the ALD line.

DP is an automatic device to place and arranges (align) dough products (sticks, cookies, biscuits, etc.) on baking trays to go straight to the oven or freezing equipment.

AUTOMATIC PRODUCTION LINE OF DOUGH PRODUCTS

STANDARD WIDTHS

.

Production capabilities of ALD line using various add on systems

| Add On System | ALD Configuration | Products | |

|---|---|---|---|

| Basic Configuration K | • EXTRUDER (ALDEX) • SEEDING SYSTEM (ALDSD) with GUILLOTINE • PLACING at trays (ALDDP) |

Breadsticks, rusks, baton sale, croutons, etc. |  |

| ADD ON Horizontal Knife +C | + Horizontal Knife (Guillotine) | + Biscuits. |  |

| ADD ON filling Unit +F | + Filling Unit (Installation Base, Special Mold & FM Filling Machine) | + Stuffed products |  |

| ADD ON Ring Unit +R* | + Ring Unit (Ring Installation, Ring Mold & Pneumatic devices) *Diameter of the Rings Mold: – ALD200 from 25mm to 160mm -ALD600, ALD800 and ALD1000 from 25mm to 80mm |

+ Bread Rings |  |

| ADD ON Braiding Unit +P | + Braiding Unit (Mold & Motor) | + Braided products |  |

| ADD ON Bagel Forming Unit +B* | + Bagel Forming Unit. A special forming conveyor that forms the dough in bagel shape. Different diameters requires different forming conveyor. *Available only for 200mm (ALD200) models |

+ Bagels |  |

.

Productivity Table

| Used system Kind of Products |

ALD 200 (200mm conveyor width) |

ALD 600 (600mm conveyor width) |

ALD 800 (8000mm conveyor width) |

ALD 1000 (100mm conveyor width) |

|---|---|---|---|---|

| Guillotine for linear Products e.g. breadstick (medium diameter) |

80kg/h*1 | 250kg/h*1 | 360kg/h*1 | 410kg/h*1 |

| Rings Unit e.g. Bread-rings |

720-840 strokes/h*2 | 720-840 strokes/h*2 | 720-840 strokes/h*2 | 720-840 strokes/h*2 |

| Horizontal Cutting e.g. Cookies |

1500-1800 strokes /h*2 | 1500-1800 strokes /h*2 | 1500-1800 strokes /h*2 | 1500-1800 strokes /h*2 |

*1: Weight of dough before baking and proofing.

*2: Product dimension and line’s width defines the number of products produced at each stroke.

e.g. A typical mold for cookies of ALD600 has 9 holes. The number of cookies produced each hour is equal to 9 times the number of strokes per hour.

.

Relevant Posts

New innovative extruder – Production of large Breadrings (Koulouri, Simit)

. . Play Video PLAY on VIMEO Breadring (koulouri [...]

ALD200CKR+EBSF Installation at Israel

Play Video PLAY on VIMEO We have successfully installed an automatic production line for Bagels [...]

Eliana Bakery. Bread-stick production by ALD line

Play Video Our client Dimitris Petridenas(Eliana Bakery) produce rusks and breadstick (kritsini) by our automatic [...]

Installation of a ALD600CKR line at Cyprus

Play Video PLAY on VIMEO EBAK has successfully installed an Automatic Line for Dough products [...]

Jawad Modern Bakeries

Play Video PLAY on VIMEO Jawad Modern Bakeries Co are the Most Leading Bakeries [...]