EBAK TM RANGE

Tart and pie shell production machines.

Highly productive and flexible machines, suitable for both large food industries and confectionery and bakery workshops.

TM MODELS

KEY FEATURES

At Fully automatic models (TM-L / TM-L PLUS / TM-S) the molded pans or alu-foils plates are conveyed by a chain conveyor under the volumetric head (extruder or dose hopper) which deposits the required quantity of dough inside mold. The heated press forms the tarts. Then the ready tarts/pies are exported into the output conveyor.

A Filling head can be placed after the output conveyor to fill the tarts/pies with one or more fillings.

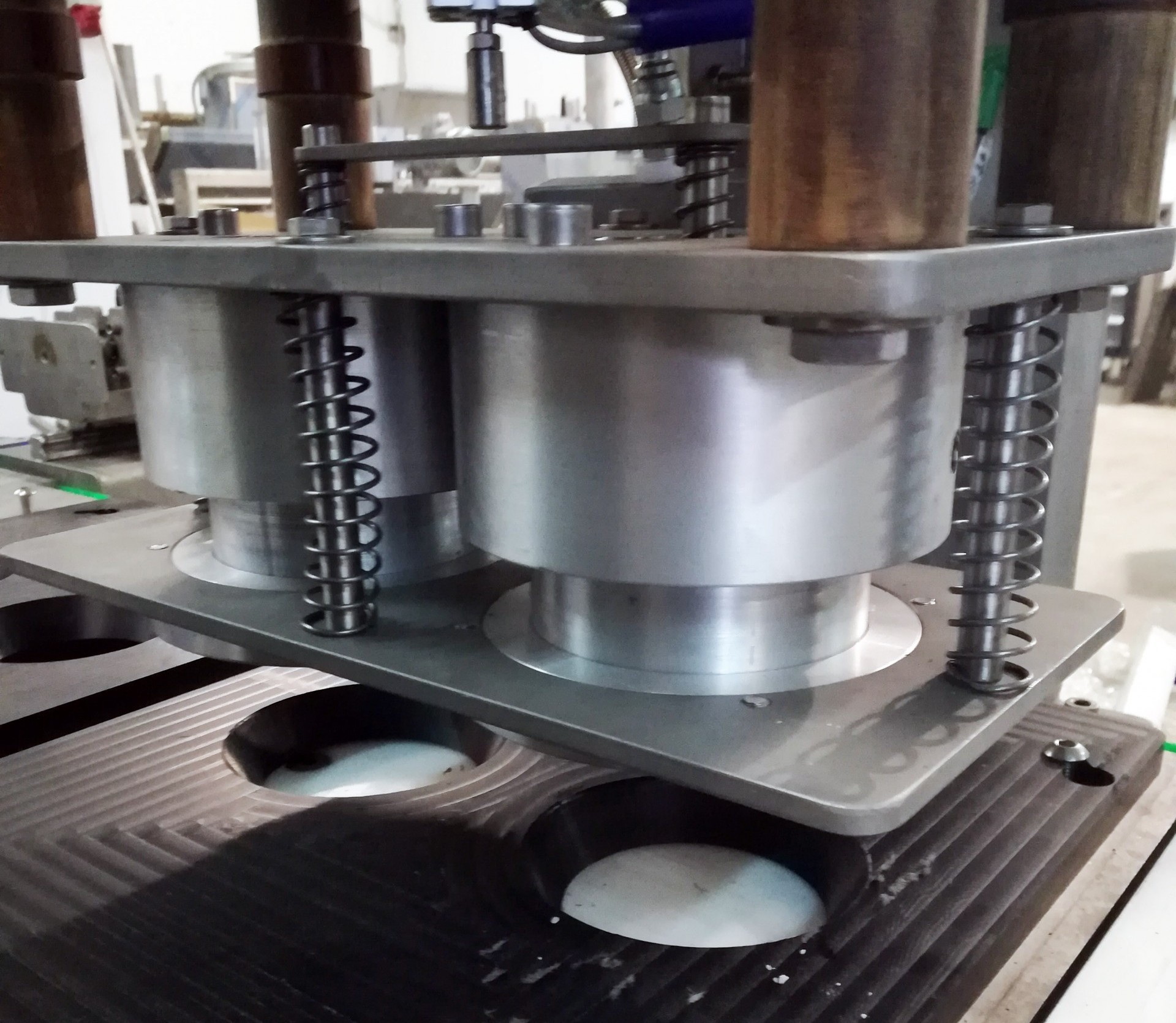

Forming Press

- Ptm is a low-cost solution for tart and pie production easily, accurately, rapidly, safely. The operator puts manually the baking pan and the dough at the case. When the operator press the start button (or the foot-pedal) machine aligns the baking pan with the shaping die. The die enters into the case and forms the dough.

Dossing Head

- The Semi-automatic Dough Dosage unit (Dtm) is the perfect “companion” of Ptm. The operator puts manually the baking pan at the case. Then press the start button (or the foot-pedal) and Dtm deposit the required dossage of dough at baking pan. Dtm is a low-cost solution easy operated,accurately, rapidly,safely.

.

Relevant Posts

Automatic Rotating Tart Shell Production Machine by ΕΒΑΚ

The new Automatic Rotating Tart Shell Production Machine by ΕΒΑΚ installed in Toulouse France Tart and pie shell [...]

Tart machine in the Philippines by ΕΒΑΚ

The new automatic tart shell machine TMS by ΕΒΑΚ The new automatic tart shell machine TMS The machine is [...]

Installation of Tart Shell machine (TMS) at Rountas Company

Play Video TMS key features: -Accurate dosage -Tart shell with diameter 2cm-12cm -Capacity 25 pcs/minutes [...]